Why So Many Boeing 737 Airplanes Are Having Accidents

It seems like Boeing has dominated media headlines lately, and the news doesn't look good. After a seemingly endless spate of accidents involving the company's once-beloved 737 aircraft, Boeing now faces lawsuits, economic woes, and consumer distrust. Two major crashes claimed the lives of 346 people within five months of each other. A door plug blew off an Alaska Airlines flight in January 2024. An engine cover flew off a Southwest Airlines flight in early April. These are just a few reasons to be wary of boarding what Simple Flying called "one of the most successful aircraft in history."

Are you wondering why so many Boeing 737 airplanes have experienced accidents and whether you should steer clear of flying in one? You're not alone! That's why we've spent countless hours digging deep into the research to determine what's causing these catastrophic events. Armed with the knowledge we gained from international news agencies, aviation experts, and the FAA, we've determined the main reasons behind the many incidents involving Boeing 737s. Buckle your seat belt and get ready for a turbulent ride through Boeing's rocky and often deceitful history and the truth behind its aircraft's most tragic accidents.

The most recent Boeing 737 accidents

Two of Boeing's most catastrophic plane crashes have occurred on the same type of aircraft, a 737 Max 8. In October 2018, an Indonesian Lion Air flight plummeted into the Java Sea, killing all 189 people on board. The second crash, operated by Ethiopian Airlines, happened six minutes after take off in March 2019, causing 157 fatalities. These weren't the first crashes involving a 737 plane. In 1991, a United Airlines flight crashed in Colorado, killing 25 people, and a USAir plane carrying 131 people crashed near Pittsburgh in 1994.

More recently, an engine cover blew off a 737-800 operated by Southwest Airlines in April 2024. According to the Wall Street Journal, this accident occurred upon takeoff, and no injuries were reported despite the cover hitting a wing flap upon its descent. Earlier in the year, a 737-800 operated by United Airlines landed at an Oregon airport without one of its external panels. No injuries were reported, and the airline claimed that "there was no indication of any damage to the plane during the flight," per The New York Times. Another incident occurred in February on a 737 Max 8 operated by United Airlines. The plane's rudder pedals became stuck upon landing. And in January, an Alaska Airlines flight lost its door plug mid-air.

Sub-par engineering standards

While people once hailed Boeing for its engineering expertise, its focus on financial gain has led to fatal design flaws and system errors. As stated by The Atlantic, this "company once driven by engineers became driven by finance." In recent years, only one of Boeing's senior management positions was filled by an engineer named Stan Deal, who retired in March 2024. The Financial Times reported that Emirates Airlines chief Tim Clark was so worried about Boeing's "progressive decline" in standards that he planned to send engineers to supervise the production of the Boeing 777.

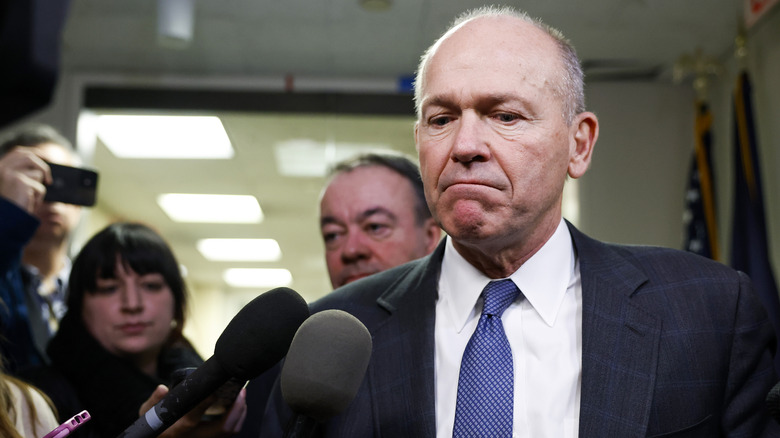

Emirates will also oversee staff at Spirit AeroSystems (a company that manufactures airplane fuselages for Boeing). Since Clark's airline is one of the biggest clients of the struggling aircraft maker, he has a vested interest in ensuring the safety of the planes. Amid a major shuffle at Boeing headquarters (CEO Dave Calhoun will leave at the end of 2024, and board chair Larry Kellner will part ways in May), Clark told CNBC that "the company needs a strong engineering lead as its head coupled to a governance model which prioritizes safety and quality."

Failure to comply with quality control measures

During an investigation of the Alaska Airlines door plug incident, the FAA claimed it discovered "multiple instances where the companies allegedly failed to comply with manufacturing quality control requirements." The investigators found Boeing had issues with handling and storing aircraft parts. According to NPR, the National Transportation Safety Board found four bolts missing from the door plug that blew off during the flight. Spirit AeroSystems, a Boeing subcontractor, replaced five faulty rivets on the fuselage at a Boeing factory months before the accident. The plane returned to service without the bolts being reinstalled. Whether the missing bolts were due to an error on the part of Spirit AeroSystems or Boeing has yet to be determined.

Another major concern raised by the FAA was Boeing's alleged failure to adhere to manufacturing and product control requirements. Mike Whitaker, an FAA Administrator, told The New York Times that his agency will be "'closely scrutinizing and monitoring production and manufacturing activities." Almost 200 Boeing 737 aircraft have been grounded during the investigation (via Forbes). The FAA has also stopped production expansion of the Boeing 737 Max.

Software failure

Both the Lion Air and Ethiopian Airlines crashes resulted from a flight-control software called MCAS. A new addition to the original 737 models, pilots of the newer planes weren't familiar with this software, and many were never told it existed. The Associated Press said MCAS wasn't listed in the aircraft or training manuals. Boeing did not initially tell pilots or airlines of the existence of this software, which it designed to lower the plane's nose in emergencies where the nose tilted up.

Due to the 737 Max's design, its nose tended to tilt up at times, hence the addition of MCAS. According to CNN, Boeing kept this system "almost secret" because it believed it would only need to be used in "extreme flying circumstances." During both crashes, the system activated unintentionally because of a faulty sensor. The pilots were unable to correct the situation.

In an interview with NPR, reporter and author of "Flying Blind: The 737 MAX Tragedy and The Fall of Boeing," Peter Robinson claimed there was poor communication during the development of the MCAS system. Upper management reportedly ignored engineers with valid questions. When one employee asked what would happen if a sensor malfunctioned, Robinson said, "He was told, 'If that happens, the system shuts down immediately.' And that was completely not true."

Cost-cutting measures compromise safety

A Bloomberg article claims the safety concerns with the Boeing 737 Max resulted from the company's "relentless cost-cutting." According to the news agency's interviews with former Boeing engineers, Boeing staff focused more on aspects like low costs than on important issues like passenger safety. Bloomberg reporter and author of "Flying Blind: The 737 MAX Tragedy and the Fall of Boeing" Peter Robinson has discussed Boeing's downward spiral from an engineering- and quality-driven company to one focused more on saving money and outsourcing work to increase profits.

To cut costs, Boeing reportedly moved sections of the company (like the pilot training simulators) to different states to avoid working with unions. It gained "$60 million in state and local tax credits over 20 years" by moving its headquarters from Seattle to Chicago, claimed former Medtronic CEO Bill George in an op-ed for Harvard Business School. This moved engineers further away from management, making communication difficult.

The MCAS system, too, was allegedly developed to save the company money. According to Robinson's interview with NPR, when Boeing realized the 737 Max could stall when its nose moved upwards, it implemented MCAS instead of redesigning it. Recreating the plane would have slowed the aircraft's production and increased expenses. Unfortunately, Boeing chose not to properly train pilots on MCAS because flight simulators are expensive (about $10 million each), Robinson stated.

Focusing on profit

Boeing's obsession with turning a large profit has led to repeated criticism. As CNN reported, some aviation experts and Boeing critics believe problems with the 737 stems from the company's profit-chasing corporate culture. Boeing staff, they claim, "put profits ahead of the safety and engineering prowess for which it was once praised." Former Boeing employee and current executive director of the Foundation for Aviation Safety, Ed Pierson, told CNN that Boeing's "leadership is more concerned with getting the planes out the door than quality." U.S. Senator Richard Blumenthal agreed, telling Today that "Boeing is putting profits and production speed ahead of quality and safety."

This didn't use to be the case, wrote former Boeing physicist Stan Sorscher in a letter to The Seattle Times. In the 1990s, Boeing was known for building the safest, most well-designed planes. After merging with McDonnell Douglas in 1997, experts believe things began to change for the worse. According to an article in Chronline, management "treated experienced engineers and machinists as expendable." The company focused on profit-boosting measures like outsourcing. "For years, we prioritized the movement of the airplane through the factory over getting it done right, and that's got to change," Boeing CFO Brian West said.

Turning a blind eye to safety

The Associated Press reported that Michael Whitaker, FAA Administrator, implied that Boeing has put safety on the backburner in favor of turning out more aircraft. In a hearing about aviation safety, Whitaker told the House Transportation subcommittee," The current system is not working because it is not delivering safe aircraft." The New York Times reported that engineers flagged the Alaska Airlines Boeing 737 Max 9 plane the day before the door plug accident.

According to research conducted by the newspaper, the staff "were so concerned about the mounting evidence of a problem" that they wanted to pull the aircraft from flight rotation and have it serviced. About a week before the accident, the same plane was sent to maintenance for issues with a front passenger entry and an exit door. After returning to service, the aircraft's pressurization warning light illuminated twice, the last time just two days before the incident.

Shifts in leadership

According to multiple sources, including Bill George (former Medtronic CEO), who penned an op-ed for Harvard Business School, Boeing's main issues can be traced back to Philip Condit, the company's CEO, during its acquisition of McDonnell Douglas. In 2003, Condit was "forced to resign" due to ethical issues (he allegedly had affairs with employees and demonstrated questionable business practices), reported The New York Times. Harry C. Stonecipher replaced Condit, lasting just 15 months on the job before also being ousted for having an affair with an employee. He was succeeded by Jim McNerney, who remained in the role for 10 years before leaving in 2015.

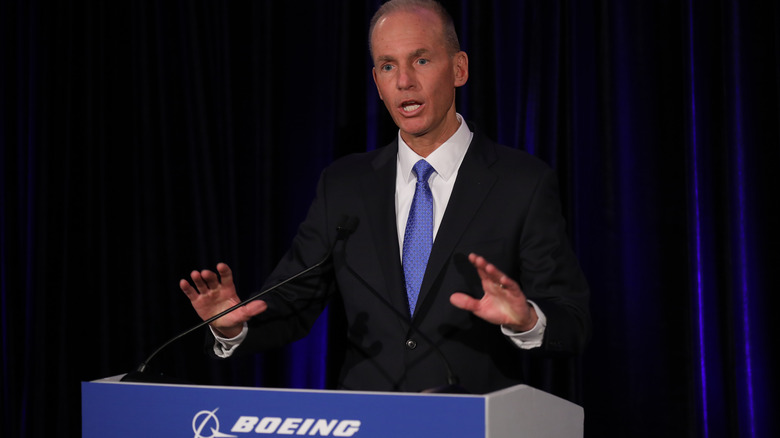

With Boeing in the hot seat for its role in the fatal 2018 and 2019 crashes, the company fired Dennis Muilenburg, the CEO who took over for McNerney, claiming it did so to "restore confidence," reported PBS. David Calhoun took over the position in January 2020. He was at the helm when the door plug blew off that Alaska Airlines flight and when the engine cover flew off the Southwest Airlines flight in April. The company will have to find yet another CEO following Calhoun's 2024 departure.

A history of safety issues

Boeing endured repeated safety issues years before the 2018 and 2019 crashes. The Washington Post reported that the FAA caught a Boeing subcontractor manipulating cargo door certifications on the company's 777 aircraft. This had reportedly been going on for years before government regulators found out. The Washington Post said the FAA clamped down on the company's many perceived infractions in 2015, ordering it to address its "broader corporate culture and governance issues."

The FAA demanded that Boeing be more honest and forthcoming about its practices and fix issues to ensure that its planes meet federal safety requirements. Common complaints included tools abandoned in the aircraft wings and wire bundles that weren't installed properly, resulting in chafing, which could cause pilots to lose control of the plane as it entered a roll. Despite its 2015 agreement with the FAA, Boeing continued to miss deadlines for fixing safety problems.

It keeps redesigning the same model

CNN labeled Boeing's 737 aircraft "the most successful airliner ever made and one whose future is more uncertain than ever." The 737 experienced its first official wheels up in 1967 and was sold to 17 airlines. At the time, this efficient aircraft was deemed smaller and more cost-efficient than the company's predecessors. Boeing was "the undisputed dominator of the industry," reported New York Magazine." Fast forward almost 50 years, and that same plane is still found on runways (and falling from the skies) in various reiterations across the globe.

Instead of starting from scratch and investing in the research and engineering necessary to develop a new aircraft, Boeing executives repeatedly tweaked its original model. The 737-300 was released in 1984, a redesign that lengthened and widened the fuselage to carry more passengers and included a bigger engine. As CNN stated, "The success of this upgrade set aside initial plans to design an entirely new, more modern aircraft."

The company realized it could simply build upon the aircraft's original frame, soon launching the 737 Next Generation versions that were even longer and had greater fuel capacity. In 2011, Boeing released its fourth generation 737, the Max. The New York Times states this aircraft "was the company's best selling jet ever, with hundreds of billions of dollars in advance orders from airlines around the world." Then, it began to crash and fall apart, changing everything.

Allegedly untruthful employees

Before approving the Boeing 737 Max for commercial use, the FAA conducted extensive evaluations of the aircraft. During this time, two Boeing technical pilots allegedly deceived FAA investigators about MCAS changes, supposedly concealing system information. By keeping this information from the FAA, the U.S. Department of Justice claimed that Boeing conspired to "defraud the Federal Aviation Administration's Aircraft Evaluation Group." Despite these claims, a federal jury later acquitted one of the technical pilots of felony charges of deceiving the Federal Aviation Administration.

During the company's deferred prosecution agreement with the Department of Justice, David P. Burns, Acting Assistant Attorney General of the Department's Criminal Division, said, "Boeing's employees chose the path of profit over candor by concealing material information from the FAA concerning the operation of its 737 Max airplane and engaging in an effort to cover up their deception." The company agreed to pay more than $2.5 billion in penalties for its perceived infractions.

Even newer aircrafts have safety concerns

As if travelers weren't worried enough about the safety of Boeing's 737 aircraft, two whistleblowers have expressed major concerns with Boeing's 787 Dreamliner. In an interview with BBC, John Barnett, a former Boeing quality control manager, claimed that 25% of the 300 oxygen systems he tested for the 787 Dreamliner were faulty. He suggested that the company's hurry to build new aircraft resulted in impaired safety practices. Boeing disputed the validity of his claims. On the third day of his deposition against Boeing in March 2024, staff found Barnett dead in his car outside his hotel (via New York Magazine).

In an April 2024 interview with Today, Lisa Banks, the attorney of another whistleblower, Sam Salehpour, stated, "he is alleging that Boeing knowingly took a series of manufacturing shortcuts in the construction of the 787." As a result, Salehpour, an engineer who worked at Boeing for over 10 years, believes the new Dreamliner jet could "break apart" while flying due to mistakes in constructing the fuselage. The company responded: "These claims about the structural integrity of the 787 are inaccurate and do not represent the comprehensive work Boeing has done to ensure the quality and long-term safety of the aircraft."